Hello! In today’s competitive manufacturing landscape, efficiency is paramount. Every aspect of your operation, from raw materials to finished goods, needs to be tightly controlled and optimized. This is where Enterprise Resource Planning (ERP) software comes in.

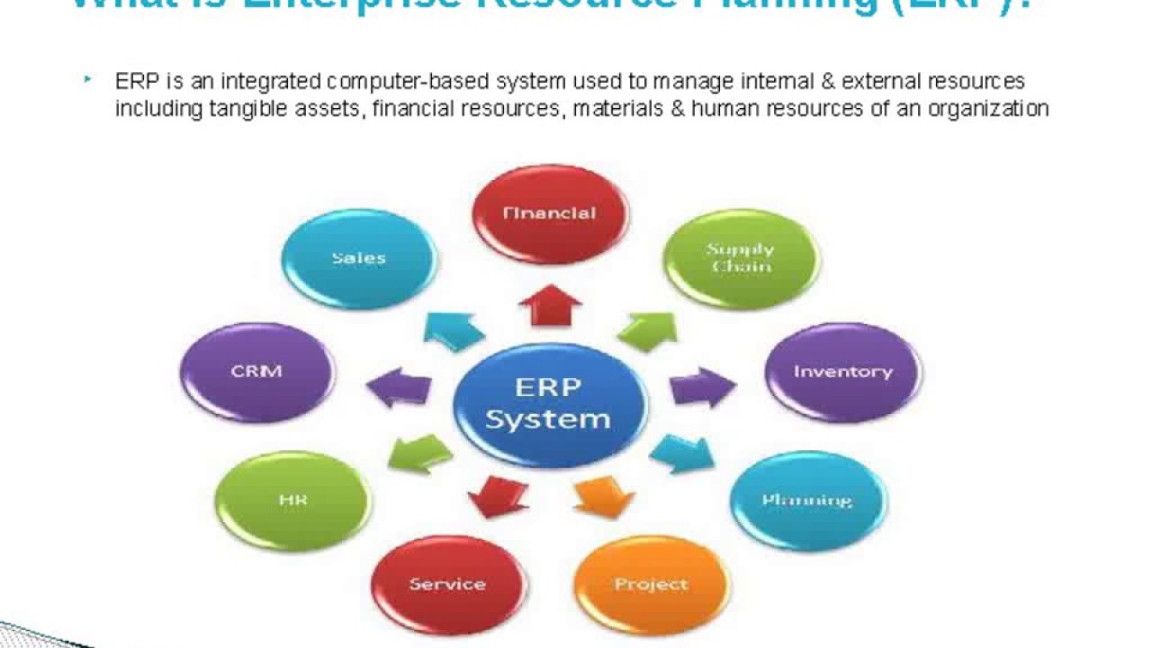

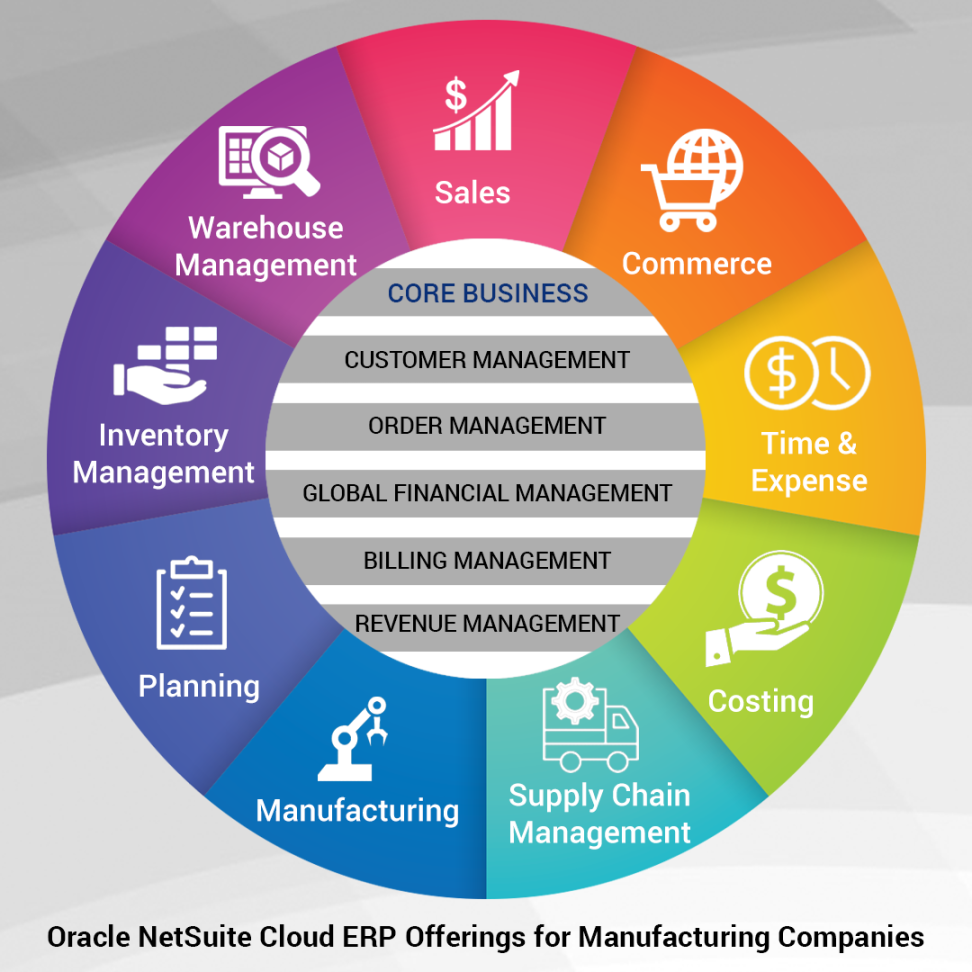

What is ERP for Manufacturing?

ERP is a comprehensive business management solution that integrates core functions across an organization. In the manufacturing industry, an ERP system specifically caters to the unique needs of production processes. It acts as a central hub, connecting departments like production, inventory, finance, and sales. This centralized data platform provides real-time insights and streamlines workflows, leading to significant improvements in efficiency and profitability.

Key Benefits of ERP for Manufacturers

Enhanced Production Planning and Scheduling: ERP software empowers manufacturers with robust production planning tools. It facilitates the creation of detailed production schedules, taking into account material availability, machine capacity, and labor requirements. This allows for better resource allocation, reduced lead times, and on-time delivery.

Improved Inventory Management

Managing inventory effectively is crucial for any manufacturer. An ERP system provides a clear picture of inventory levels across all stages of production, from raw materials to finished goods. This enables manufacturers to optimize stock levels, minimize waste, and ensure they have the right materials on hand to meet production demands.

Streamlined Supply Chain Management

ERP fosters seamless communication and collaboration with suppliers. Manufacturers can gain real-time visibility into supplier performance, track material deliveries, and identify potential bottlenecks. This proactive approach strengthens supply chains and reduces the risk of disruptions.

Increased Quality Control

Maintaining consistent product quality is essential for manufacturers. ERP systems can be integrated with quality control procedures, allowing for real-time monitoring of production processes and product specifications. This enables early detection of defects and prompt corrective actions, leading to improved product quality and reduced rework costs.

Enhanced Customer Relationship Management (CRM)

ERP integrates seamlessly with CRM functionalities, providing a unified platform for managing customer interactions. Manufacturers can gain valuable insights into customer needs, track order fulfillment, and provide better after-sales support. This fosters stronger customer relationships and improves overall customer satisfaction.

Improved Financial Visibility and Control

ERP software provides manufacturers with a consolidated view of their finances. It integrates accounting functions, automates financial transactions, and facilitates real-time budgeting and forecasting. This empowers manufacturers to make informed financial decisions, optimize resource allocation, and improve profitability.

Increased Collaboration and Communication

ERP breaks down departmental silos by providing a single source of truth for all business-critical data. This fosters improved communication and collaboration across the organization. Teams have access to real-time information, enabling them to make data-driven decisions and work together more effectively.

Regulatory Compliance

Manufacturing operations are often subject to stringent regulations. ERP systems can be configured to comply with industry-specific standards, ensuring accurate record-keeping and reporting. This helps manufacturers avoid compliance issues and fines.

Improved Decision Making

ERP empowers manufacturers with real-time data and business intelligence tools. This enables them to make data-driven decisions across all areas of operation, from production planning to inventory management and resource allocation. Informed decision-making leads to improved efficiency, cost savings, and increased profitability.

Increased Flexibility and Scalability

As your manufacturing business grows, your ERP system should keep pace. Modern ERP solutions are designed to be scalable and adaptable. They can be easily customized to meet the evolving needs of your business, allowing you to add new functionalities and integrate with other systems as needed.

Improved Risk Management

ERP systems offer valuable risk management capabilities. By providing real-time data on inventory levels, supplier performance, and production processes, manufacturers can identify and mitigate potential risks. This proactive approach helps to ensure business continuity and minimize disruptions.

Enhanced Data Security

Manufacturing operations often involve sensitive data, such as product designs and customer information. Modern ERP systems prioritize data security. They incorporate robust access controls, encryption protocols, and disaster recovery measures to safeguard your critical business data.

Choosing the Right ERP System for Your Manufacturing Needs

With a wide range of ERP solutions available, selecting the right system for your business is crucial. Consider factors such as your company size, industry-specific functionalities, budget, and scalability requirements. Conducting thorough research, consulting with industry experts, and seeking demos from different vendors can help you make an informed decision.

Implementing an ERP System Successfully

Successful ERP implementation requires careful planning and execution. Involve key stakeholders from across the organization, develop a clear implementation plan, and provide adequate training to your employees. A phased approach can also be beneficial, allowing you to roll out the system in stages and minimize disruption.