In today’s competitive manufacturing landscape, efficiency is paramount. Every second counts, every penny saved makes a difference, and every ounce of visibility into your operations is crucial for informed decision-making. That’s where Enterprise Resource Planning (ERP) software comes in.

What is ERP Software for Manufacturing?

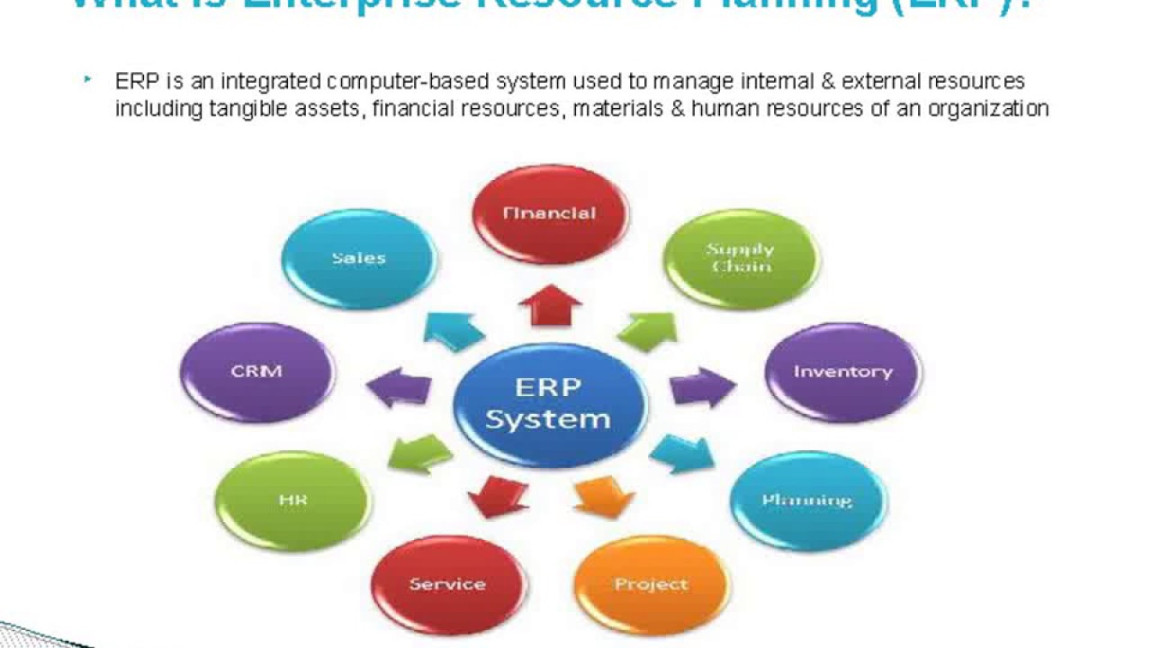

ERP software acts as the central nervous system of your manufacturing business. It integrates all core business processes – from production planning and inventory management to finance and customer relationship management (CRM) – into a single, unified platform. This eliminates data silos, fosters collaboration across departments, and provides real-time insights into your entire operation.

Key Benefits of ERP Software for Manufacturers

Increased Efficiency: Streamline workflows, automate repetitive tasks, and optimize production scheduling with ERP software. This reduces lead times, improves on-time delivery rates, and frees up valuable resources for strategic initiatives.

Enhanced Inventory Management: Gain complete control over your inventory levels with real-time visibility into raw materials, work-in-progress (WIP), and finished goods. ERP software helps you identify and eliminate waste, reduce stockouts, and optimize purchasing decisions.

Improved Quality Control: Ensure consistent product quality with robust quality control features built into your ERP system. Track defects, manage non-conforming materials, and implement corrective actions efficiently.

Stronger Financial Management: ERP software provides a consolidated view of your finances, streamlining accounting processes, automating financial reporting, and improving budgeting and forecasting accuracy.

Enhanced Customer Satisfaction: ERP software improves your responsiveness to customer inquiries and orders. Track customer interactions, manage service requests effectively, and deliver a superior customer experience.

ERP Features Tailored for Manufacturing

Beyond the core functionalities of an ERP system, manufacturing-specific features offer even greater value.

Production Planning & Scheduling: Create detailed production plans, schedule resources effectively, and track production progress in real-time.

- Bill of Materials (BOM) Management: Define and manage complex product structures with accurate BOMs, ensuring you have the right materials on hand for production.

- Shop Floor Control: Track work orders, monitor machine performance, and manage labor efficiently on the shop floor.

- Supply Chain Management: Gain greater visibility into your supply chain, optimize procurement processes, and collaborate effectively with suppliers.

- Quality Management System (QMS): Implement a robust QMS within your ERP system to manage non-conformances, conduct audits, and ensure regulatory compliance.

Choosing the Right ERP Software for Your Manufacturing Business

With a wide range of ERP solutions available, selecting the right one for your business is crucial. Here are some key factors to consider:

Company Size and Needs: ERP solutions cater to businesses of all sizes. Evaluate your specific needs and choose a system that scales with your growth.

- Industry Specialization: Some ERP systems cater to specific manufacturing industries, offering industry-specific functionalities and best practices.

- Deployment Options: Cloud-based ERP offers flexibility and scalability, while on-premise deployments provide greater control over your data.

- Implementation Cost and Time: ERP implementation can be a complex process. Consider the upfront costs and time commitment required for each solution.

The Implementation Journey: Planning for Success

A successful ERP implementation requires careful planning and collaboration. Here are some key steps to ensure a smooth transition:

Define Your Business Requirements: Clearly identify the areas you want to improve and the functionalities you need in an ERP system.

- Select a Qualified Implementation Partner: Choose an experienced partner who understands your industry and can guide you through the entire implementation process.

- Data Migration and System Integration: Develop a comprehensive plan for migrating your existing data and integrating the ERP system with other business-critical applications.

- Change Management and User Training: Prepare your employees for the new system by providing comprehensive training and ongoing support.

The Long-Term Benefits of ERP for Manufacturers

Implementing an ERP system is an investment in the future of your manufacturing business. The benefits extend far beyond immediate operational improvements. Here’s what you can expect in the long run:

Improved Business Agility: ERP software empowers you to adapt to changing market conditions and customer demands more quickly and effectively.

- Enhanced Data-Driven Decision Making: With real-time data at your fingertips, you can make informed decisions to optimize your operations and achieve strategic objectives.

- Increased Innovation: ERP frees up resources and allows you to focus on innovation, product development, and exploring new market opportunities.

- Sustainable Growth: A well-implemented ERP system lays the foundation for sustainable growth, ensuring your business is equipped to scale and thrive in the competitive landscape.