Hello! In today’s competitive manufacturing landscape, efficiency and visibility are paramount for success. That’s where NetSuite Manufacturing comes in – a cloud-based solution designed to streamline your entire production process, from sales order to finished goods. This comprehensive guide will delve into the key functionalities of NetSuite Manufacturing, explore its benefits for businesses of all sizes, and explain how it can empower you to gain a competitive edge.

Unifying Your Manufacturing Workflow

From Sales Orders to Shop Floor Production

NetSuite Manufacturing seamlessly integrates your manufacturing workflow, eliminating data silos and ensuring real-time information throughout the entire process. This begins with capturing sales orders and translating them into actionable production plans. NetSuite then facilitates the creation of work orders, which define the materials, labor, and machinery required to fulfill each order. With real-time inventory visibility, NetSuite ensures you have the necessary components on hand to avoid production delays.

Crafting Bills of Materials (BOMs) with Ease

Defining the Building Blocks of Your Products

Bills of Materials (BOMs) are essential for any manufacturing operation, outlining the precise components needed to assemble a finished product. NetSuite Manufacturing empowers you to create and manage complex BOMs with ease. You can define multi-level BOM structures, manage revisions, and track component usage in real-time. This ensures production accuracy and simplifies cost calculations.

Production Planning and Scheduling Made Simple

Optimizing Resource Allocation and Delivery Times

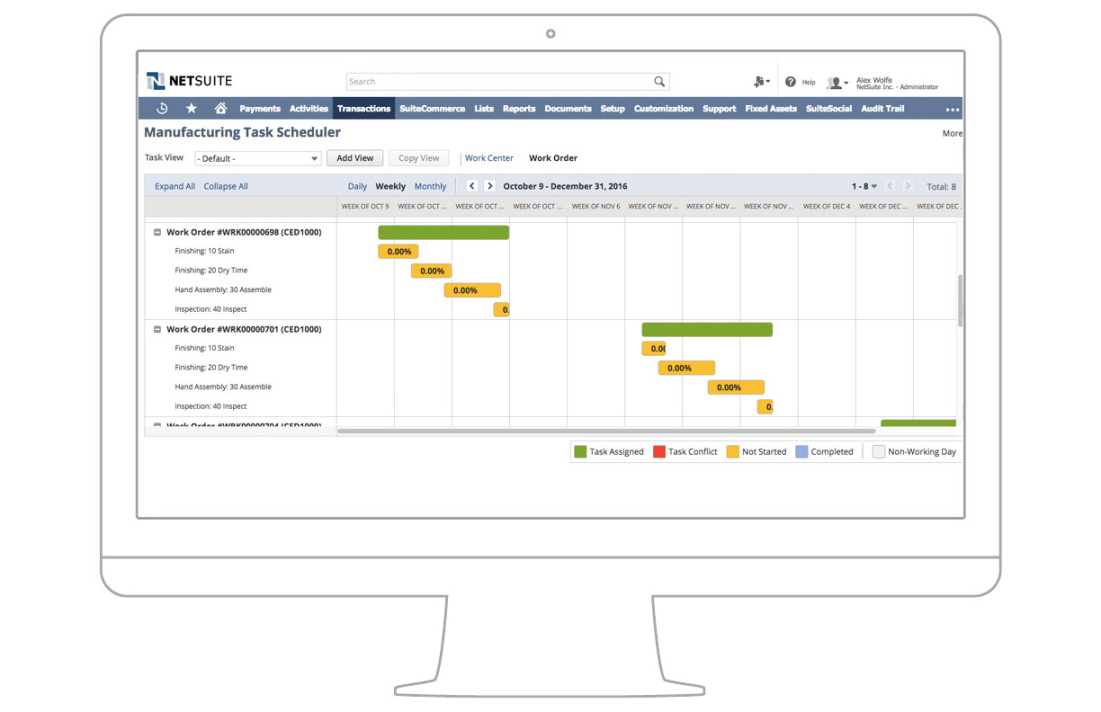

Effective production planning is crucial for maximizing efficiency and meeting customer delivery deadlines. NetSuite Manufacturing offers robust production planning and scheduling capabilities. You can utilize finite capacity planning to allocate resources based on real-time production capacity and material availability. This allows you to optimize production schedules, minimize bottlenecks, and ensure on-time delivery.

Visibility Throughout the Production Process

Real-Time Data for Informed Decision-Making

NetSuite Manufacturing provides real-time visibility into every stage of the production process. You can track work order progress, monitor material consumption, and identify potential issues before they disrupt operations. This comprehensive data empowers you to make informed decisions that optimize production flow, reduce waste, and improve overall efficiency.

Simplifying Inventory Management

Maintaining Optimal Stock Levels and Reducing Costs

Inventory management is a critical aspect of any manufacturing operation. NetSuite Manufacturing provides a centralized platform for managing inventory levels, from raw materials to finished goods. With real-time inventory visibility, you can optimize stock levels, reduce carrying costs, and ensure you have the necessary materials on hand to fulfill customer orders promptly.

Driving Quality Control and Compliance

Ensuring Consistent Product Quality and Meeting Regulations

Maintaining consistent product quality is essential for any manufacturer. NetSuite Manufacturing offers features to streamline quality control processes. You can define inspection points within the production process, capture quality data, and generate reports to identify and address quality issues promptly. This helps ensure product consistency and compliance with industry regulations.

Empowering Your Workforce with Mobile Access

Real-Time Information at Your Fingertips

In today’s dynamic manufacturing environment, access to real-time information is crucial for your workforce. NetSuite Manufacturing offers mobile capabilities that empower your production personnel with the information they need on the go. Workers can access work order details, track inventory levels, and capture production data directly from the shop floor using mobile devices.

Advanced Planning and Replenishment (APS)

Automated Inventory Management for Increased Efficiency

For manufacturers with complex supply chains, Advanced Planning and Replenishment (APS) can be a game-changer. NetSuite Manufacturing offers built-in APS functionality that utilizes demand forecasts and production plans to automatically generate purchase orders for raw materials. This ensures you have the necessary materials on hand to meet production demands without overstocking inventory.

Financial Management Integration

Streamlining Operations and Gaining Financial Insights

NetSuite Manufacturing seamlessly integrates with NetSuite’s robust financial management suite. This allows you to track production costs in real-time, generate accurate product cost calculations, and streamline financial reporting. With a unified view of your finances and production operations, you can make data-driven decisions that optimize profitability.